A critical discussion of how Samsung Electronics achieves quality in its Value chain.

January 18, 2022 2022-01-18 20:12A critical discussion of how Samsung Electronics achieves quality in its Value chain.

A critical discussion of how Samsung Electronics achieves quality in its Value chain.

Need a paper like this one? Get in touch via the email address or order form on our homepage.

1. Introduction

Wiengarten et al. (2013) in their study on innovative approaches to quality practices note that quality has become a central issue of concern for organisations and that minimisation of costs while maximising value is every manager’s goal. In addition to this Alnawaiseh, AL-Rawashdi and Alnawaiseh (2014) claim that an understanding of the value chain and using it, through quality improvement and cost reduction, can help achieve and sustain competitive advantage. In view of these insights, this report seeks to analyse how a firm can attain quality in its value chain by addressing pertinent questions- what is quality, the essence of quality in manufacturing, how a firm can ascertain conformance to quality and the role of quality in creating competitiveness. Samsung, an electronics manufacturing company is used as a case example.

2. Overview of quality characteristics of a product

The element of quality has been under constant discussion by researchers and as Sower and Fair (2005) posit, the result is that the definition of quality takes the perspective of the context to which it is applied. However, they emphasize that the wide definition of quality in the manufacturing field is ‘conformance to standards’. In a different perspective quality has been defined as ‘innate excellence’ a definition which Wai Mun and A. Ghani (2013) has been more universal. However, this definition has been phased out by modern business practices that redefine quality based on the customer. It is from such that the distinctions of transcendent-based and user-based definitions exist. According to Wicks and Roethlein (2009) a study of manager showed that a majority of them define quality according to the level of customer satisfaction.

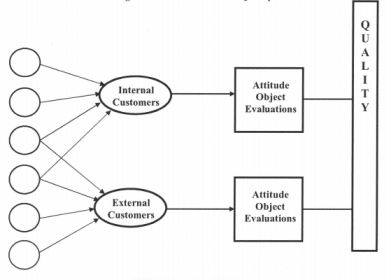

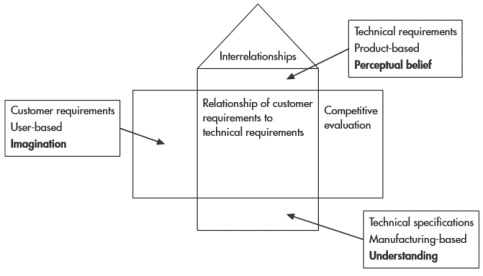

In other words, the definition of quality in the manufacturing industry is based on the users of the products. In this case, quality is said to be achieved only when the customer is fully satisfied and the product has fulfilled the intended usage. As illustrated in appendix 1, this definition of quality takes into account the feedback of the customers both internal and external. However, a different approach to quality is presented by Sower and Fair (2005) under which they blur the line between product-based, user-based and manufacturing-based definition of quality. In their view, all the three aspects are internally consistent as they just need to be aligned by the quality manager. The interaction of these three views into one starts with understanding of end-user needs and ends in translation of the same into technical terms. This is illustrated in appendix 2. Lastly, Jakpar et al. (2012) discussing on product quality elements and customer satisfaction coins the definition of quality as excellence, value for money, conformity to standards and customer satisfaction. This definition integrates all the approaches to product quality.

3. The essence of quality in manufacturing

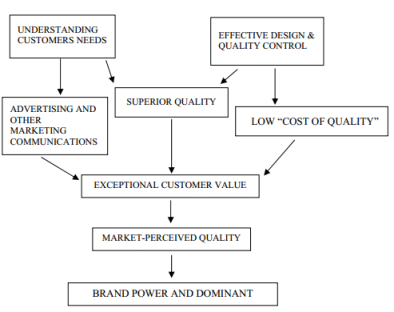

The contemporary business world in characterised by intense competition and thusly it is paramount for a firm to create a competitive edge over other players in the industry. Vantamay (n.d.) avers that the end-user perception of quality equates the success of a particular product in the market. Specifically the assertion is that perceived quality directly influences the profit margins, brand power, market share, brand equity and perceived value. These elements combined determine the sustainability of a firm in the long-run. Their culmination into determining brand power and market dominance is illustrated in appendix 3.

The main goal that managers need to be pursuing is elimination of intentional error commission by employees. As Octavian (2014) infers, the ‘do not do evil knowingly’ concept is fundamental in overall employee quality control. In addition to this Wiengarten et al. (2013) sustain that keen control of quality in the manufacturing process is associated with better overall organisation performance. This is because quality management practices specifically cut down on unnecessary costs thus pacing up financial performance and increase waste reduction which saves on procurement costs.

Essentially, quality management at the manufacturing level, in the view of Gharakhani et al. (2013), reduces the need for unnecessary inventory by stabilising the production process and consequently cuts down on throughput time. According to Sila (2007), shortening the throughput time improves on delivery performance. Sadikoglu and Olcay (2014) do also believe that cost efficiency is the central achievement of quality management. The elements of quality management in manufacturing that Sadikoglu and Olcay (2014) point at are process management, cross-functional product designing, supplier quality checks and end-user involvement.

An important element in quality attainment in production that Ooi et al. (2011) majors on is the relationship between quality, customer satisfaction and firm performance. Basically, customer satisfaction is dependent on product quality since as inferred earlier, quality means a product achieving the intended use and this equates to satisfying the customers. Shirin (2011) crowns this by noting that customer satisfaction influences brand loyalty and in the words of Kumar, Batista and Maull (2011), influences organisational performance. It is therefore factual to aver that quality in manufacturing is imperative in overall firm performance.

In the example of Samsung electronics, the overall quality of the company dictates providing the best products that exceed customer requirements and expectations (Samsung, 2015). This can be linked to the exemplary performance of Samsung as a best performer in terms of brand loyalty rivalling even best players such as Apple Inc (Shaughnessy, 2014). Evidenced in their annual report in 2013 is that Samsung cut costs in production by integrating efficient – waste reducing – technologies and thus was able to manufacture affordable products that have inevitably continued to mark the success of the firm (Samsung Electronics, 2013). Similarly, according to the International Business Times, Samsung has managed the quality-price balance by moving to cheaper manufacture locations and getting better suppliers of component parts (Arakali, 2015).

4. How Samsung can ascertain conformance to quality standards in the value chain

According to Arumugam, Rouhollah and Chettiar (2011), in the current competition realms, the customer serves as the start rather than the end to quality concepts. This means that firm consider what customers want before engaging in the manufacture of a product. Thusly, if a product impresses the customer and reflects this in terms of sales then it can be termed as quality. It is based on this argument that Andelkovic Pesic and Vucicevic (2012) note that financial performance should be taken as the best indicator of quality adherence. Jahanshahi et al. (2011) on the other hand argues out and interrelationship between product quality and the level of customer satisfaction as well as loyalty. In this perspective, the customer also acts as an indicator of quality because the more a firm wins customers into becoming loyal the more quality its products are perceived to be. In the case of Samsung the same can be evidenced in the impressive performance that the firm has had against major competitors in the recent years. It is ranked as one of the most valuable brands (Shaughnessy, 2014). In addition to these perspectives, a different argument is raised by Zakuan et al. (2012) that focuses on employees as the part of the success factors in quality implementation. As such, a determinant of adherence to quality practices can be extrapolated to be the level of employee satisfaction.

An additional perspective as to whether a firm is adhering to quality standards is the determination of both internal and external policy guidelines. According to Octavian (2014), the concept of ‘zero defects and zero nonconformity’ should apply to every organisation. As such, the internal quality policy guidelines are the rule and non-conformity means the level of deviation from the rules. A similar case applies to observance of global standards of manufacturing such as the ISO 9000 certificates that are accorded to players that fulfil certain levels of quality (Singh, 2013). In general, from the highlighted determinants of quality conformance, it can be inferred that the organisational performance is the major determinant of adherence to quality standards. This is especially so in the assessment of specific areas such as customer satisfaction (through sales and loyalty), financial performance and deviation from objectives or goals.

Relating the above discussion to Samsung electronics, the same attributes of quality are evident. Firstly, Samsung’s definition of quality is customer-centric (Millar, 2014). This means their measurement of success is the level of customer satisfaction and ascription to the Samsung brand. Secondly, in the report authored by Millar (2014) a senior executive at Samsung notes that there is a shared vision of quality that incorporates employees and the employers. They adhere to this vision and to the quality charter and global regulations in doing business. This means that deviations from the vision and the quality guidelines as in the quality charter and global rules (depending on the locations) indicate non-conformity. As such, it is evident that the measures of adherence to quality standards are as highlighted above.

5. The role of quality in creating a competitive advantage

Singh (2013) begins his article by noting that a company that constantly satisfies most of the customers’ needs is referred to as a quality company. The innate characteristics of such a company include using marketers to collect the information about customer preference then using it to create products that satisfy the customer. They also invest heavily in research and development. Singh (2013) continues to note that quality in the key to value generation and customer satisfaction. As postulated earlier, customer satisfaction leads to brand loyalty and according to Allender and Richards (2012) brand loyalty is a major driver of competitiveness. Essentially, when the customer is the central piece in the entire market then issues regarding the customer become determinants of the competitive edge. Grecu (2014) summarises this concept well by noting that in a society charged with customer demands, the essence of quality has increased for firms. In addition, Grecu (2014) avers that with such the definition of competition could be defined as innovation, demanding customers and quality. This places quality as a critical issue in competing.

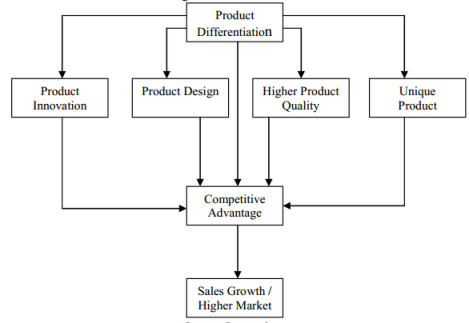

khasawneh, Al – Zoub and AL – Hashem (2012) while discussing total quality management as a way of implementing quality in manufacturing notes the imperative nature of quality in competing at organisational levels and at national levels. Specifically, the discussion points at the ability of quality in outputs (products) to influence customers’ preference for one brand over another. The balance between the quality and the price is also of importance though it is through quality that a firm can carry out differentiation and price discrimination concurrently (Herweg, 2011: Choudhary et al., 2005). In support of this approach, Dirisu, Ibidunni and OluwoleIyiola (2013) elaborate that through product differentiation – product design, product innovation, high product quality and uniqueness of a product – a firm is able to create a competitive advantage and consequently growth of market share and sale. The interrelationship between these elements is presented in appendix 4. In summary, quality determines the likability of the product which in turn influences customer satisfaction and preference for a product (loyalty) thus giving a firm advantage over its competitors.

An interview by the Forbes Magazine to a more than a decade consultant of Samsung Kevin Keller evidences the impact of quality in competition at Samsung. In the past few years Samsung was not an effective competitor in the electronics industry. However, in over the last two decades the firm has restructured and reengineered its processes resulting in production of superior products. Adamson (2013) notes Samsung’s quality quest has placed it ahead of long-time competitor – Sony electronics. Samsung implemented the strategy of ‘points of parity and points of difference’; they beat Sony electronics at quality (a quality which Sony had been good at) and used a different element of quality (design) to outdo Sony – differentiate from Sony. Lastly they implemented the price-quality balance.

6. Conclusion

The concept of quality in the value chain is a fundamental issue that concerns any contemporary business enterprise. Although having a rather amorphous definition, quality proves to be instrumental in the creation and sustenance on competitiveness. In the manufacturing sector, quality is important based on the fact that it drives customer satisfaction. These does not end here as it also, according to Vantamay (n.d.), quality directly influences the profit margins, brand power, market share, brand equity and perceived value. Similarly, quality has a role in creating a competitive edge by offering differentiation capabilities. In the case of Samsung, conformance to quality standards, noted through overall performance, has enabled it to rise to the world’s largest electronics manufacturer competing against lon-time players such as Apple Inc and Sony Electronics.

7. References

Adamson, A. (2013) The Top Three Things Samsung Did To Surpass Sony (Online) Forbes. Available at: http://www.forbes.com/sites/allenadamson/2013/07/10/the-top-three-things-samsung-did-to-surpass-sony/ (Accessed 18 Mar. 2015).

Allender, W. and Richards, T. (2012) ‘Brand Loyalty and Price Promotion Strategies: An Empirical Analysis’, Journal of Retailing, 88(3), pp.323-342.

Alnawaiseh, M., AL-Rawashdi, F. and Alnawaiseh, M. (2014) ‘The Extent of Applying Value Chain Analysis to Achieve and Sustain Competitive Advantage in Jordanian Manufacturing Companies’, International Business Research, 7(8).

Andelkovic Pesic, M. and Vucicevic, V. (2012) ‘Quantification of quality: The indicators of justification of the improvement of processes and product quality’, Economics and Organisation, 9(4), pp.485-506.

Arakali, H. (2015) Why Samsung’s Move To Build Smartphones In Vietnam Will Help It Better Compete In China (Online) International Business Times. Available at: http://www.ibtimes.com/why-samsungs-move-build-smartphones-vietnam-will-help-it-better-compete-china-1724014 (Accessed 18 Mar. 2015).

Arumugam, M., Rouhollah, A. and Chettiar, V. (2011) ‘Total quality management in the Irani’, In: 5 th International Quality Conference. pp.487-496.

Choudhary, V., Ghose, A., Mukhopadhyay, T. and Rajan, U. (2005) ‘Personalized Pricing and Quality Differentiation’, Management Science, 51(7), pp.1120-1130.

Dirisu, J., Ibidunni, O. and OluwoleIyiola, p. (2013) ‘Product differentiation: a toolof competitive advantage and optimal organizational performance’, European Scientifc Journal, 9(34), pp.258-281.

Gharakhani, D., Farahmandian, A., Farrokhi, M. and Rahmati, H. (2013) ‘Total Quality Management and Organizational Performance’, American Journal of Industrial Engineering, 1(3), pp.46-50.

Grecu, I. (2014) ‘Enhance Competitiveness through Total Quality Management and its Components’, AMM, 6(57), pp.951-955.

Herweg, F. (2011) ‘Relaxing competition through quality differentiation and price discrimination’, J Econ, 106(1), pp.1-26.

Jahanshahi, A., Gashti, M., Mirdamadi, S. and Nawaser, K. (2011) ‘Study the Effect s of Customer S ervice and Product Quality on Customer Satisfaction and Loyalty’, International Journal of Humanities and Social Science, 1(7), pp.253-260.

Jakpar, S., Angelyn, G., Johari, A. and Myint, K. (2012) ‘Examining the Product Quality Attributes That Influences Customer Satisfaction Most When the Price Was Discounted: A Case Study in Kuching Sarawak’, International Journal of business and social science, 3(23), pp.221-265.

khasawneh, S., Al – Zoub, W. and AL – Hashem, A. (2012) ‘Application of total quality management system and its impact on competition policy in industrial plants’, Journal of commerce, 4(3), pp.17-32.

Kumar, V., Batista, L. and Maull, R. (2011) ‘The Impact of Operations Performance on Customer Loyalty’, Service Science, 3(2), pp.158-171.

Millar, W. (2014) Culture of Quality: Accelerating growth and Performance in the enterprise. Forbes Insights (Online) New York: Forbes Media. Available at: http://asq.org/culture-of-quality/files/culture-of-quality.pdf [Accessed 18 Mar. 2015].

Octavian, A. (2014) ‘Zero defects and Zero non conformities’, Economy Transdisciplinarity Cognition, 17(2), pp.35-42.

Ooi, K., Lin, B., Tan, B. and Yee Loong Chong, A. (2011) ‘Are TQM practices supporting customer satisfaction and service quality?’, Journal of Services Marketing, 25(6), pp.410-419.

Sadikoglu, E. and Olcay, H. (2014) ‘The Effects of Total Quality Management Practices on Performance and the Reasons of and the Barriers to TQM Practices in Turkey’, Advances in Decision Sciences, 2014, pp.1-17.

Samsung Electronics, (2013) 2013 Samsung Electronics Annual Report. Annual Reports (Online) Samsung. Available at: http://www.samsung.com/us/aboutsamsung/investor_relations/financial_information/downloads/2013/2013-samsung-electronic-report.pdf (Accessed 18 Mar. 2015).

Samsung, (2015) Quality Policy | Samsung Semiconductor Global Website (Online) Available at: http://www.samsung.com/global/business/semiconductor/support/quality-assurance/quality-management/quality-policy (Accessed 18 Mar. 2015).

Shaughnessy, H. (2014) Why Apple Is Losing Ground To The Samsung Brand (Online) Forbes. Available at: http://www.forbes.com/sites/haydnshaughnessy/2014/01/11/why-samsung-is-gaining-on-apple-as-best-loved-brand/ (Accessed 18 Mar. 2015).

Shirin, A. (2011) ‘Customer satisfaction, brand trust and variety seeking as determinants of brand loyalty’, African Journal of Business Management, 5(30), pp.8-36.

Sila, I. (2007) ‘Examining the effects of contextual factors on TQM and performance through the lens of organizational theories: An empirical study’, Journal of Operations Management, 25(1), pp.83-109.

Singh, M. (2013) ‘Product Quality for Competitive Advantage In Marketing’, International Journal of Business and Management Invention, 2(6), pp.5-8.

Sower, V. and Fair, F. (2005) ‘There is more to quality than continuous improvement’, The quality Management Journal, 12(1), pp.8-20.

Vantamay, S. (n.d.) Understanding of Percei ved Product Quality: Reviews and Recommendations. 1st ed (Ebook) Available at: http://www.bu.ac.th/knowledgecenter/epaper/jan_june2007/Somphol.pdf (Accessed 18 Mar. 2015).

Wai Mun, T. and A. Ghani, M. (2013) ‘Continuous Improvement in Nursing Education through Total Quality Management (TQM’,. EduLearn, 7(4), p.193.

Wicks, A. and Roethlein, C. (2009) ‘A satisfaction-based definition of quality’, Journal of business and Economic studies, 15(1), pp.82-97.

Wiengarten, F., Fynes, B., Cheng, E. and Chavez, R. (2013) ‘Taking an innovative approach to quality practices: exploring the importance of a company’s innovativeness on the success of TQM practices’, International Journal of Production Research, 51(10), pp.3055-3074.

Zakuan, N., Muniandy, S., Saman, M., Ariff, M. and Sulaiman, S. (2012) ‘Critical Success Factors of Total Quality Management Implementation In Higher Education Institution: A Review’, International Journal of Academic Research in Business and Social Sciences, 2(12), pp.19-32.

8. Appendix

8.1. Appendix 1: Illustrated definition of quality

8.2. Appendix 2: Plato’s explanation of quality

8.3. Appendix 3: Perceived product quality and brand power

8.4. Appendix 4: Quality as a driver of competition

![[Solved] ENGL147N - Week 7 Assignment- Final Draft of the Argument Research Paper](https://prolifictutors.com/wp-content/uploads/2023/01/Solved-ENGL147N-Week-7-Assignment-Final-Draft-of-the-Argument-Research-Paper--240x142.png)

![[Solution] - NR305 - Week 3 Discussion: Debriefing of the Week 2 iHuman Wellness Assignment (Graded](https://prolifictutors.com/wp-content/uploads/2022/06/Best-Answer-NR305-Week-3-Discussion-Debriefing-of-the-Week-2-iHuman-Wellness-Assignment-Graded--240x142.png)

![[Best Answer] NR305 - Week 2 Discussion: Reflection on the Nurse’s Role in Health Assessment (Graded)](https://prolifictutors.com/wp-content/uploads/2022/06/Best-Answer-NR305-Week-2-Discussion-Reflection-on-the-Nurses-Role-in-Health-Assessment-Graded-240x142.png)

![[Best Answer] NR305 - Week 2 Assignment: Wellness Assessment: Luciana Gonzalez (iHuman) (Graded)](https://prolifictutors.com/wp-content/uploads/2022/06/Best-Answer-NR305-Week-2-Assignment-Wellness-Assessment-Luciana-Gonzalez-iHuman-Graded--240x142.png)