Omega Industries – Consultancy Brief/Proposal Case Study (Answered/Solved)

July 27, 2021 2021-07-27 8:23Omega Industries – Consultancy Brief/Proposal Case Study (Answered/Solved)

Omega Industries – Consultancy Brief/Proposal Case Study (Answered/Solved)

Consulting at Omega Industries

Please read the case study included in the coursework brief and complete all the three tasks outlined below. Assume you are the consultant (Timothy Edwards) for the purpose of completing this case study-based assignment.

- Identify the issues/challenges/problems that Omega Industries is facing currently, elaborate on the issues considering the context of this organisation and industry. In short, carry out a detailed issue analysis of the situation facing Omega Industries. (1000 words).

- Identify the stakeholders who have a stake in the issues/challenges/problems at Omega Industries. Following the identification of stakeholders, carry out a detailed stakeholder analysis in the context of challenges that Omega Industries is facing. (600 words).

The above two parts of this assignment should be written to demonstrate your understanding of the case and its context as an external consultant. As a consultant, you need to establish the issues and identify the main stakeholders including what needs to be focused upon in the light of the problems/situation and client requirements. The issue analysis and stakeholder analysis that you put together here will help in drafting a consulting proposal to potentially win work from the client (Omega Industries).

- Prepare a short proposal offering your consulting services to Omega Industries, with the aim of providing them with possible solutions (including relevant options) and recommendations. For the purposes of outlining project milestones/deliverables, you can assume that your initial consulting project will run for a period of 3-4 months (September to December). Within your proposal, you should cover the typical elements of a consulting proposal. You are not required to provide any cost estimates in your proposal. (1400 words).

Your proposal needs to be a comprehensive, well thought-through and a finalised piece of work based on the information provided in the case (including reasonable assumptions) rather than a preliminary draft.

Need a copy of this paper? Order here – https://prolifictutors.com/place-order/

Background and Problem

‘Well, that has been most fruitful’, said Timothy Edwards, senior consultant with Phoenix Resource International Inc.

‘It’s imperative that we meet again, but this time with Bert Fischer, and at your head office. You have my CV to give him?’ continued Timothy.

Felix Benjamin, Director of Operations Control (DOC) of Omega Industries (OI) nodded, shook hands with Timothy and left.

Timothy sat down, reflected on the meeting, and flipped through his notes. The meeting had been arranged at the request of Felix Benjamin. He had said that he wished to talk with a consultant who could help key personnel in his organisation manage imminent changes.

At the meeting, he had stated that his organisation had already implemented substantial changes. Timothy had paid special attention to the history of the company. In the topsy-turvy world of electronic office equipment, Omega Industries, a subsidiary of a large multinational American corporation, with approximately 3000 employees had shown a healthy profit in the late1990s and early 2000s. However, in the context of the worldwide economic downturn, its performance had slipped.

Omega Industries, with its head office in London, had begun to show a dip in profits, and latterly a loss, exemplified by the following figures:

2014-15 £150 million profit

2015-16 £100 million profit

2016-17 £50 million profit

2017-18 £50 million profit

2018-19 £10 million loss

2019-20 £20 million loss

The American parent company had decided to appoint an American as chief executive officer (CEO) on the departure of the previous CEO in early 2018. On his arrival, this new CEO stated that he would not tolerate any further decline in profits. He acknowledged that OI faced certain problems that might take some time to put right. However, he expected that by late 2020 the company would break even.

OI currently manufactures a range of office reprographic equipment, varying from small portable photocopiers to the latest, large, sophisticated electronic photocopiers. On certain product lines, the company had wasted time, money, and effort in updating them. On other lines, despite minor design changes, the company had manufactured the same product line for the past seven years.

The CEO of the parent company had quickly moved to appoint a new CEO at OI, Hank White, in late 2018. White was aware of the problems he confronted. Although no one had stated it, he knew that, as far as the parent company was concerned, he only had a limited period of time (unspecified) to turn the company around. He recognised that the parent company had only a limited interest in reprographic equipment, as it had diversified substantially into other fields.

He saw the parent company really as a finance house, managing a number of separate businesses.

This parent company is really not too sympathetic if any of those businesses did not perform to expectation.

It was recognised in the USA that other key positions needed to be filled. In early 2019, Bert Fischer had been appointed as director of business services (DBS). The only other new appointment was that of Felix Benjamin, as director of operations control (DOC) in April 2019, when the post became vacant. The board was completed by four other directors in the areas of HR, product manufacture, product design and financial control together with the company secretary. According to Benjamin, he was appointed to pursue an uncompromising policy of cutbacks. He considers his track record to be the reason he was offered the job. One of his previous positions was as director of production with a British medical equipment manufacturer. He had found their key plants to be badly mismanaged.

Need a copy of this paper? Order here – https://prolifictutors.com/place-order/

The problems he had identified at OI were as follows: poor product quality, inability to meet project completion dates, supervisors who had lost control of the workforce, and high labour turnover. Benjamin initiated a redundancy programme at OI, with the cooperation of the HR department, both at the local and head office level. This redundancy programme has been concentrating on managerial, professional, and administrative staff. Up to now, he has made 372 staff redundant.

Further, Benjamin had attempted to examine the operator expenses of the business services division. This division is the revenue-earning part of the organisation – it sells photocopying equipment. Despite substantial opposition from Fischer and other senior managers, Benjamin has imposed cuts in bonus payments and restrictions on company cars. The relationship between Fischer and Benjamin seems tense. Benjamin reports that Fischer resents his attempts to tighten up the business services division, as Fischer was appointed to do just that. Benjamin states that Fischer is incompetent and was only appointed as he is a long-established manager in the parent company and a friend of the CEO.

It was no surprise that Benjamin reported that morale within both management and workforce was low. He also considered management to be ineffectual and ineffective. The reason Benjamin had approached Timothy Edwards was that the company needed to concentrate on ways of increasing revenue. The cost-cutting exercise is virtually complete. No one in the company has considered ways of increasing revenue.

Timothy sat back and reflected on all this information. Within a week, Benjamin contacted Edwards to come to the head office and meet Fischer.

Meeting with Fischer (DBS) and Benjamin (DOC)

‘I’m aware of my responsibilities, Felix’, stated Fischer acidly. ‘I know this is the revenue-earning part of the organisation, but have you been listening to what I’ve been saying for this past hour? Selling photocopiers is not easy. You don’t seem to understand that!’ The meeting between Edwards, Fischer and Benjamin had started at 9.30 am.; it was now 11.30 am. The tension between the two men was obvious. Timothy, in his usual style, listened, commented little and made numerous notes. As the two men argued, he glanced through his notes. They read as follows:

- Benjamin states Business Services has too many staff

- Fischer disagrees because he feels the process of selling office equipment is not understood or appreciated within OI.

- Fischer considers the problem that Business Services is facing to be that of poor staff motivation and a lack of effective communication between managers.

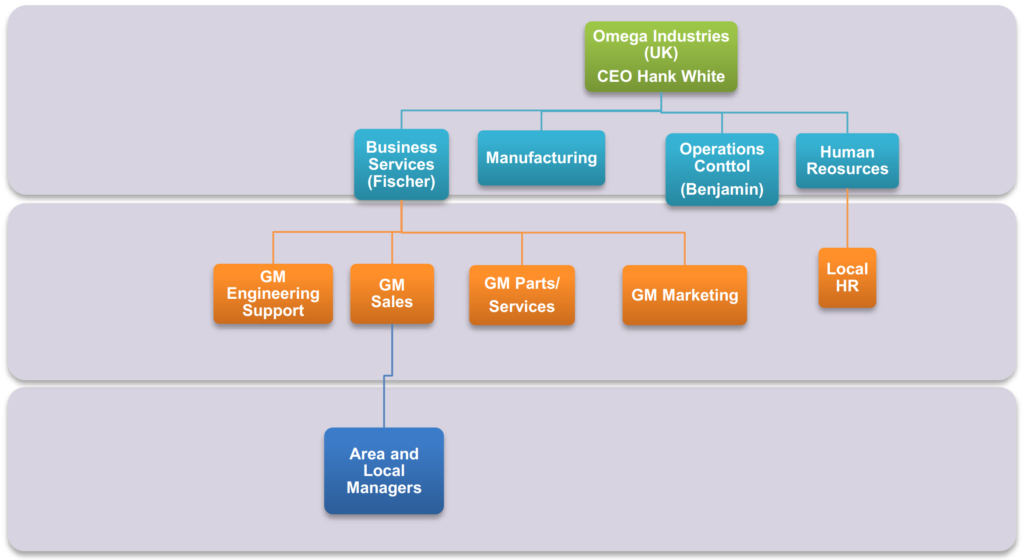

‘I wonder if I could interrupt’, said Timothy cutting across Benjamin and Fischer’s heated argument. ‘For me to make sense of what you are saying, I need to see and understand your organisational structure.’ Fischer responded immediately and took out of his top drawer a sheet of paper which had been folded several times, unfolded it, and spread it over his desk (see the organisation chart below).

Organisational Structure – Omega Industries

‘Now, Business Services is split into four major parts, and these are …’ began Fischer.

Need a copy of this paper? Order here – https://prolifictutors.com/place-order/

‘I see’, said Timothy. ‘Now, can you tell me something about your business, as I know little about it? For instance, how do you sell?

‘Basically, it’s simple. We have large customers who purchase equipment in bulk and also retailers who may order some of our larger equipment but would basically stock the smaller equipment, responded Fischer.

‘I see! Then what? From the organisation structure, I see you provide support services.’

‘Yes, these are our engineers. Their job is to provide support, if and when needed. Really, it is up to the customer to contact the engineering support service. Our response is quick – we say and mean within a day’, replied Fischer.

‘Fine. Thank you. I think I have an overall picture. Hmm … in order to understand some of the problems you are facing, I think I need to interview some of your managers. Is that possible?’ asked Edwards.

‘Yes of course. I think that is very necessary,’ responded Benjamin. ‘Now, it’s probably right that you see some of the other directors, more to get a general picture, but you need to see most of the key people in Business Services and I’ll arrange for all these interviews.’

The Interviews

‘Come in. You must be Tim Edwards. Felix Benjamin told me you’d call’, said the General Manager (GM) Sales.

This was Edwards’ fourth interview. He began his standard introduction, explaining what he was doing, and that he wanted to know how each manager spent his time, his range of duties, the perceived support, constraint, and opportunities in each manager’s job, and whether improvement of any sort was considered necessary.

‘I must emphasize that anything you say to me will be kept in the strictest confidence. I mean that’, Edwards concluded.

‘Mmm’, the GM Sales said, ‘Just how confidential is “confidential”?’

‘I mean what I say. Everything you say is absolutely confidential!’ Edwards asserted.

‘Did they tell you about the new appointments and how they are trying to put in their own people and make sure that the old hands like me who know something about this business are left out in the cold?’, said the GM Sales.

‘I think we need to talk about this, as I’ve only been told that certain new appointments have taken place’, said Timothy.

‘I think basically what has happened is that new people have been brought into the structure because people like me are considered not to be doing their job’, continued the GM Sales. ‘But you should try and work here! We are all supposed to be pulling together to satisfy the customer. That is the last thing we do. You try getting Trevor Peacock (the general manager of engineering support services) to work with you. You know if my sales team and his engineers were working better together, half of our customer problems would be solved. Let me ask you what you think. Does an engineer just service, or do they sell as well? Do they look at the other office equipment a client may have? I just can’t get Peacock to see my point of view.

The conversation continued for a further two and a half hours. It was obvious that the GM Sales felt aggrieved about the situation in particular and with the company in general. She stated a number of complaints apart from the lack of cooperation with engineering support services, and the new appointments. One of the comments made was that there existed a lack of knowledge as to the requirements of customers. GM Sales stressed this point.

Need a copy of this paper? Order here – https://prolifictutors.com/place-order/

‘It may seem strange to say it, but I think we don’t know what customers need. Our knowledge of clients is simply poor. Me, a salesperson, saying this, it’s incredible!’ were the words used by the GM Sales.

Edwards’ next important appointment was with GM Marketing.

‘From the way you’ve been talking and asking questions, it seems to me you’ve been influenced by the sales group. Look, let’s go through what marketing does’, said GM Marketing. The conversation was now 50 minutes old.

‘You must realize the competitive nature of our business. We have our rivals, and they are household names. Half of our problem is picking up the crumbs the big boys leave us. Does that mean that customers go for brand loyalty or product loyalty or just purchase what they know about? You know, if it’s the last of these three, we’ve got a problem, according to Hank White, because we aren’t getting to potential customers’, continued the GM Marketing.

‘I hope it’s not the first two because then you really have got a problem’, responded Edwards.

‘Yes, fair point!’ smiled the GM Marketing. He continued. ‘Anyhow, let me continue. Where was I? … So, in my opinion, the customer is a bit flighty; it is difficult to obtain information about customer needs; we are in a very competitive business, but also customer loyalty is so unpredictable. Yeah …’ Pause. ‘OK. That’s the outside, now what about us inside. Do you really want to know my true opinion? You’re going to think we’re terrible. I think bloody engineers and sales are the real problems. Those two don’t get on. They need to provide a full service to the customer. On top of that, GM Sales just won’t play the game. We are trying to set up a unified policy and she’s got so many different contracts with clients that if someone wants some sort of deal, they may contact me. They may then also contact sales and negotiate a separate deal. The problem is that Sales is run by someone from the past when selling was a bit of a cowboy activity. She’s operating on her own, continued the GM Marketing.

‘You understand the problem? You know, this question of information on customer trends and needs. Where do we get our information from? I think this whole organisation is too technology-driven. If I am honest, I’m not sure what questions to ask from whom. Yet, we conduct surveys, examine sales returns and try to talk to sales, if that were possible, talk to retailers, hold conferences and promotions. We try our best, finished GM Marketing.

The conversation continued for some time. Timothy interviewed most of the key managers in Business Services. The picture that was emerging was one of gloom, despondency, lack of trust and cooperation amongst managers, especially between the marketing, sales, and engineering support groups.

In addition, particular issues did emerge, such as that the forecasts made by the marketing group concerning expected demand for photocopiers per period were inaccurate, with the result that the company faced a critical problem of overstocking.

It also became clear that the engineering support service department was overspending on the budget, as most of the warranty claims, in terms of mechanical faults occurring on reprographic units under two years of age, were not being challenged and compensation was paid to the customer.

The parts department was making a profit, according to the director of parts, by analysing the pattern of demand on all spares. Part of the process of analysis involved accumulating requests for spares from the field engineers, in order to judge the pattern of the real need for particular spare parts in the various parts of the country. In this way, the director of parts could then estimate his likely expected annual stockholding capacity. By not overstocking, he was able to show a profit. Timothy recalled the comments of the general manager of engineering support services.

‘The GM parts services doesn’t realise the spares my engineers want on time. He wants to see what is real as opposed to possible demand so that he does not become overstocked. That drives me crazy. It drives me crazy because half my warranty claims arise as our customers need spares, can’t get them on time, and eventually the machines break. Well, all that means is that my guys have to collect the machine, bring it here to our workshops, repair it, and take it back to the customer. All this is bad business. Inconvenience for the customers, inconvenience for us, and as a result we lose some potentially good clients.

Need a copy of this paper? Order here – https://prolifictutors.com/place-order/

The crisis meeting

After these meetings, Edwards fed back his initial findings to the CEO of OI, Hank White, in a crisis meeting. White nodded throughout. ‘You’ve confirmed what I already knew. We have a crisis, and we need your help. The president of the group, of which OI is only one of the subsidiaries paid us an unexpected visit last week. He looked around the plants, examined the marketing forecasts and after some discussion made it clear that we need to be more profitable, probably by reorganizing the structure of the business services division, otherwise senior management of OI may be removed.’

He continued, ‘The second part of the discussion we had with the president involved the new ZB35 machine. The ZB35 is the latest in reprographic technology, designed and manufactured in the USA and has just been awarded a top design prize by the Science Society.

The president has stated that we are ready to market the ZB35 from September 2022onwards. This is just terrible! We know nothing about the product, its performance, or what spares to stock.’

‘Tim, we need a way forward. We’d like you to come in and provide your consulting services to us, building on the scoping interviews you have done. It is September 1st, 2021, now. We want you to come in over the next few months and help us overcome the issues that we are facing. By the end of December 2021, we want you to present to us a fine-tuned analysis based on the problems and issues are that we are facing, and what solutions will work for us.

‘But of course, first, you need to initiate the consulting work, Tim!! Find out even more about what the issues are. You’ve got a free hand to use whatever methodology you like to gather the data you want, for you to come up with some specific strategies and recommendations. But we need a proposal from you first of all. Just something brief, setting out what you are going to do between now and the end of December: what the key goals are; how you’re going to gather data; what the deliverables will be. A pretty standard consulting brief if you like!

Need a copy of this paper? Order here – https://prolifictutors.com/place-order/

![[Solved] ENGL147N - Week 7 Assignment- Final Draft of the Argument Research Paper](https://prolifictutors.com/wp-content/uploads/2023/01/Solved-ENGL147N-Week-7-Assignment-Final-Draft-of-the-Argument-Research-Paper--240x142.png)

![[Solution] - NR305 - Week 3 Discussion: Debriefing of the Week 2 iHuman Wellness Assignment (Graded](https://prolifictutors.com/wp-content/uploads/2022/06/Best-Answer-NR305-Week-3-Discussion-Debriefing-of-the-Week-2-iHuman-Wellness-Assignment-Graded--240x142.png)

![[Best Answer] NR305 - Week 2 Discussion: Reflection on the Nurse’s Role in Health Assessment (Graded)](https://prolifictutors.com/wp-content/uploads/2022/06/Best-Answer-NR305-Week-2-Discussion-Reflection-on-the-Nurses-Role-in-Health-Assessment-Graded-240x142.png)

![[Best Answer] NR305 - Week 2 Assignment: Wellness Assessment: Luciana Gonzalez (iHuman) (Graded)](https://prolifictutors.com/wp-content/uploads/2022/06/Best-Answer-NR305-Week-2-Assignment-Wellness-Assessment-Luciana-Gonzalez-iHuman-Graded--240x142.png)